PASS Locator equipment maintenance

The essentials of a maintenance system

1. Settable dates for maintenance of the equipment

2. IDs for the equipments item and location

3. A schedule of maintenance by location for the preset dates

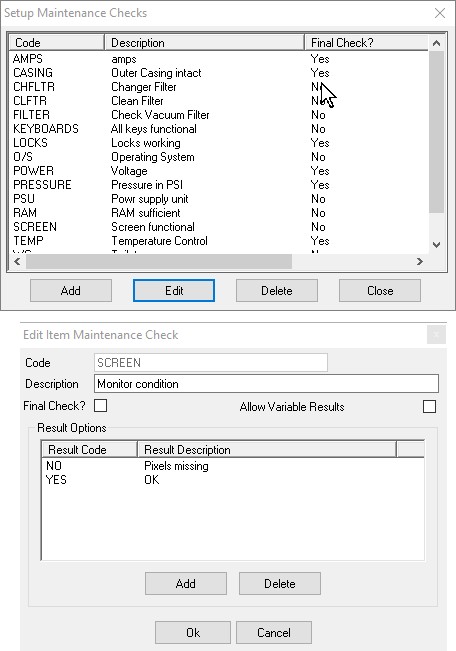

4. A set of tests and possible results that can be recorded

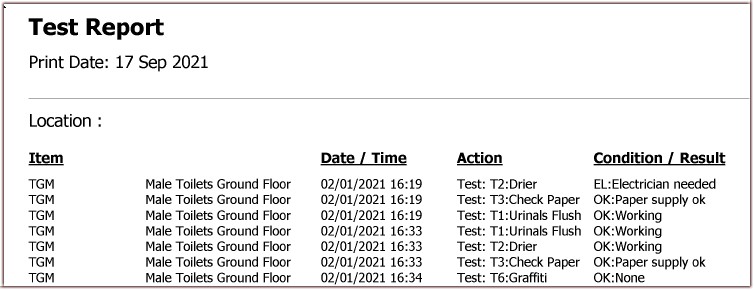

5. A method of recording those results

Maintenance Intervals

In PASS Locator each item type can have different criteria and checks assigned to it. For example, a check on a PC might record its hard disk capacity and condition of the monitor/keyboard etc whereas the state of an office chair, pressure washer or toolkit will have different criteria. When entering the category, the maintenance intervals are set up enabling scheduling to take place.

Location monitoring

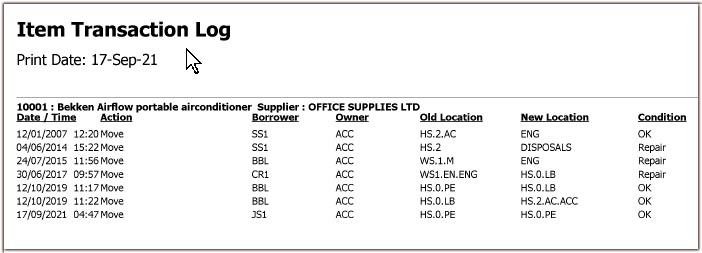

Every time the item is issued to a new user or taken to a new location the new location is recorded by scanning the barcode. Then when the maintenance schedule is run, items are listed either by category or by location. This avoids searching for items and overlooking others when the maintenance is carried out. A movement history helps to locate lost items.

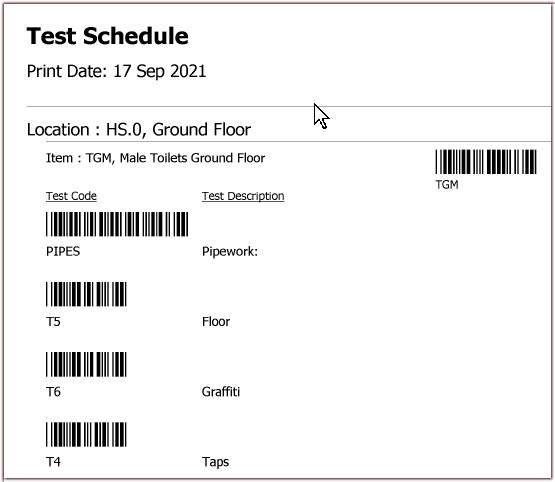

Scheduling

The barcoded maintenance schedule is run for the groups of assets and/or locations that you select, and it will show you which ones need checking together with the test codes. You can check when maintenance was last carried out and also get a report on the lists of checks done at specific times.

More details PASS Locator

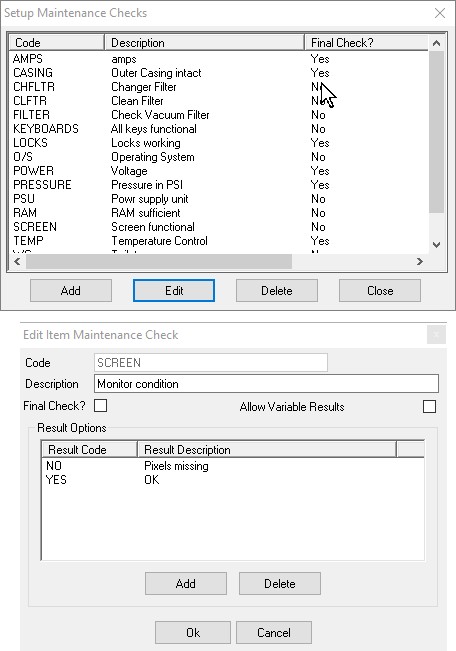

The top image shows the type of tests you have set up and the lower image shows which tests you want to apply to this piece of equipment.

The PDA scans the item code then the test code from a list or a selection on the PDA screen. This means fast maintenance recording and seamless transmssion to the records on the database where reports can then be run.

This is the loan form recording the date out and the date due back. If something cant be found, the loans report shows who is supposed to have it with date due back and current location.